Advantages of using machine extrusion: improved product adhesion and hardness

Machine extrusion technology has gradually become a way of maintaining integrity and safety in color composite wood industry. This technology has greatly changed the production process and has guaranteed the quality of colored laminated wood.

Mechanical extrusion technology makes the processing of colored laminated wood precise and efficient, giving manufacturers more confidence to bring their products to the market while ensuring consumer safety.

Understanding machine extrusion technology

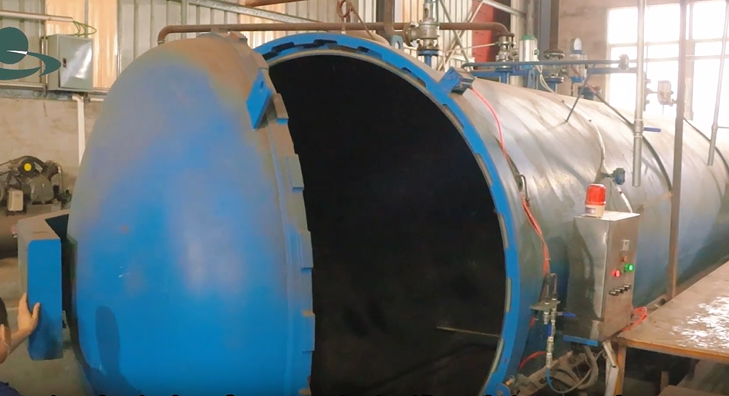

Machine extrusion technology is a kind of wood material extrusion processing through automatic equipment to form a variety of thicknesses and colors of laminated wood. This equipment is mainly composed of extruders, hot presses, cutting machines, etc. Through precise control of temperature, pressure, and speed, the wood material undergoes physical changes under high temperature and pressure, leading to the formation of colored laminated wood with unique properties.

Advantages of machine extrusion

· Make thin laminates more tightly connected.

Machine extrusion technology reduces the molecular spacing between thin wood chips through high temperature and pressure, thus making the connection closer and enhancing the strength and durability of laminated wood.

· Customization and versatility.

Machine extrusion technology can easily produce a variety of colors according to customer needs. This makes colored laminated wood products more personalized, satisfying consumers’ pursuit of unique space.

· To achieve a variety of colors through direct extrusion formation.

Machine extrusion technology can realize the direct extrusion of a variety of colors without additional coating or stickers, making the product more beautiful.

· The environment is more environmentally friendly.

The raw materials used in machine extrusion technology are mostly renewable resources, which is in line with the concept of environmental protection. At the same time, the waste generated by the machine extrusion production process can also be recycled, reducing environmental pollution.”

Frequently Asked Questions

1.How does machine extrusion ensure product quality?

By precisely controlling temperature, pressure, and speed, the machine extrusion technology enables the wood material to undergo physical changes under high temperature and pressure to form colored laminated wood with unique properties. In addition, the machine extrusion process is strictly controlled to ensure that the product has good wear resistance and pressure resistance.

2. What field can colored laminated wood be used in?

Colored laminated wood is widely used in furniture decoration, sports goods manufacturing, small object crafts, gun stock manufacturing, and other fields, and its unique color and texture provide designers with more creative space.

3.Does machine-extruded laminated wood have longer durability?

Machine extrusion technology makes thin planks join more tightly, enhancing the strength and durability of the laminated wood, giving it longer-lasting durability.

Order perfect colored laminated wood from us today

Whether you are the manufacturer or the seller in wood product industry, we can provide the best colored laminated wood. Our goal is to provide the best laminated wood to help you grow your business. Please send us a message via the Customer contact form on our website to order now.